Shenyang Sunnyjoint Chemicals Co.,Ltd., is a professional manufacturer and supplier of chemicals for rubber processing industry. The company was established in 2003, it is located in shenyang city, the famous industrial base of northeast China. The company is currently consists of a trading office, an analysis lab, a rubber accelerator factory, a rubber supplementary material factory.

SUNNYJOINT

Shenyang Sunnyjoint Chemicals Co.,ltd

NEWS CENTER

-

2019-07-22

Introduction of rubber vulcanization process knowledge

1. Traditional rubber vulcanization process 1. The main factors affecting the vulcanization process: Sulfur dosage. The larger the amount, the faster the vulcanization rate, and the higher the degree of vulcanization that can be achieved. The solubility of sulfur in rubber is limited. Excess sulfur will precipitate from the surface of the rubber, commonly known as "sulfur spraying". In order to reduce the phenomenon of sulfur injection, it is required to add sulfur at the lowest possible temperature, or at least below the melting point of sulfur. According to the use requirements of rubber products, the amount of sulfur in soft rubber is generally no more than 3%, in semi-hard rubber, the amount is generally about 20%, and the amount in hard rubber can be as high as 40% or more. Vulcanization temperature. If the temperature is 10°C higher, the curing time will be shortened by about half. Since rubber is a poor heat conductor, the vulcanization process of the product is different due to the temperature difference of its various parts. In order to ensure a more uniform degree of vulcanization, thick rubber products generally adopt gradual heating and low temperature vulcanization for a long time. 2. Vulcanization time: This is an important part of the vulcanization process. If the time is too short, the degree of vulcanization is insufficient (also known as under-sulfur). The time is too long and the degree of vulcanization is too high (commonly known as oversulfur). Only an appropriate degree of vulcanization (commonly known as positive vulcanization) can ensure the best overall performance. 2. According to vulcanization conditions, it can be divided into three types: cold vulcanization, room temperature vulcanization and hot vulcanization. 1. Cold vulcanization can be used for the vulcanization of film products. The products are immersed in a carbon disulfide solution containing 2% to 5% of sulfur chloride, and then washed and dried. 2. During room temperature vulcanization, the vulcanization process is carried out at room temperature and normal pressure, such as using room temperature vulcanizing glue (mixed rubber solution) for bicycle inner tube joints and repairs. 3. Thermal vulcanization is the main method of vulcanization of rubber products. According to different vulcanization media and vulcanization methods, thermal vulcanization can be divided into three methods: direct vulcanization, indirect vulcanization and mixed gas vulcanization. ①Direct vulcanization, the product is directly put into hot water or steam to vulcanize. ②Indirect vulcanization, the product is vulcanized in hot air. This method is generally used for some products with strict appearance requirements, such as rubber shoes. ③Air-mixed vulcanization is firstly used for air vulcanization, and then direct steam vulcanization is used. This method can not only overcome the shortcomings of steam vulcanization affecting the appearance of products, but also overcome the shortcomings of slow heat transfer due to hot air, long vulcanization time and easy aging. Three, rubber vulcanization process Before vulcanization, there is no cross-linking between the molecules of the rubber, so it lacks good physical and mechanical properties and has little practical value. When the rubber is added with a vulcanizing agent, the rubber molecules can be cross-linked by heat treatment or other methods to form a three-dimensional network structure, so that its performance is greatly improved, especially the constant tensile stress, elasticity, hardness, and tensile strength of the rubber. A series of physical and mechanical properties will be greatly improved. The process in which rubber macromolecules react chemically with the crosslinking agent sulfur under heating to form a three-dimensional network structure. After vulcanization, the rubber is called vulcanized rubber. Vulcanization is the last step in rubber processing, and can get shaped rubber products with practical value. Four, injection molding vulcanization process: The most obvious difference between ordinary molding and injection molding is that the former compound is filled into the cavity in a cold state, while the latter compound is heated and mixed and injected into the cavity at a temperature close to the vulcanization temperature. Therefore, in the injection molding process, the heat provided by the heating template is only used to maintain vulcanization, and it can quickly heat the rubber to 190℃-220℃. In the molding process, the heat provided by the heating template is first used to preheat the rubber material. Due to the poor thermal conductivity of rubber, if the product is thick, it will take a long time for the heat to be conducted to the center of the product. The use of high temperature vulcanization can also shorten the operating time to a certain extent, but it often results in scorching on the edges of the products near the hot plate. Adopting injection-pressure vulcanization can shorten the molding cycle and realize automatic operation, which is most beneficial to mass production. Injection pressure also has the following advantages: it can eliminate the preparation of semi-finished products, moulding and product trimming, etc.; it can produce high-quality products with stable dimensions and excellent physical and mechanical properties; reduce vulcanization time, improve production efficiency, and reduce the amount of rubber. Reduce costs, reduce waste, and improve business economic efficiency. 5. Matters needing attention in injection molding vulcanization process: Use reasonable screw speed and back pressure to control proper injection machine temperature. Generally, the difference between the temperature of the outlet glue and the control cycle temperature should be no more than 30 degrees. The purpose of the injection machine screw is to prepare a sufficient amount of rubber for each cycle at a selected and uniform temperature; it obviously affects the output of the injection machine. The back pressure is produced by slowing down the flow rate of the oil outlet in the injection cylinder, and restricts the rubber injected by the injection machine to the pushing effect of the injection cylinder. In practice, the back pressure will only slightly increase the shear to the rubber compound, but will not cause a decrease in the physical properties of the vulcanized product. nozzle design: The nozzle connects the injection head and the mold, and at the same time has a certain effect on the heat balance. The pressure loss through the nozzle is converted into heat by injection. The compound must never be vulcanized in this part. Therefore, it is very important to choose the right nozzle diameter, which affects the friction and heat generation at the nozzle position, the pressure required for rubber injection, and the filling time. Proper mold temperature, best vulcanization conditions. After choosing the best fit of the rubber, it is important to match the injection molding conditions with the vulcanization conditions. Compared with compression molding, injection molding has different temperature distributions on the surface and inside of the mold. To achieve good vulcanization, high-precision temperature control is necessary to make the surface and inside of the mold reach the best vulcanization conditions at the same time. High temperature will increase the shrinkage rate of rubber, but the relationship between the two is linear and should be fully estimated before production. In addition, in terms of molding pressure, high-pressure molding is extremely advantageous, because pressure is inversely proportional to shrinkage. Safe and reasonable rubber formulation design. For the rubber compound for injection vulcanization molding, it is required to have the following characteristics: The Mooney scorch time of rubber compound should be as long as possible to obtain maximum safety. Generally, the Mooney scorch time should be 2 times longer than the residence time of the rubber in the barrel. The vulcanization speed is fast. Through the reasonable selection of different rubber vulcanization systems and the addition of suitable accelerators, the rubber has a satisfactory efficiency during injection pressure vulcanization. Good fluidity, good fluidity reduces the residence time of the rubber compound, reduces the injection pressure time, and improves the anti-scorch ability. Six, nitrogen vulcanization process The main advantages of vulcanization with nitrogen filling are energy saving and prolonging the life of the capsule, which can save 80% of steam and double the life of the capsule. Tyres consume a lot of heat and electricity during the vulcanization process, so it is of great significance to develop and promote energy-saving vulcanization processes. Due to the small molecular weight and small heat capacity of nitrogen, when the nitrogen is filled into the inner cavity of the tire capsule, it will not absorb heat and cause the temperature to drop, and it is not easy to cause the oxidative cracking of the capsule. Seven, the process characteristics of nitrogen vulcanization First pass high temperature and high pressure steam, after a few minutes, switch to pass in nitrogen, and use the "pressure-holding and variable-temperature" process of nitrogen-filled vulcanization until the end of vulcanization. Because the heat of the first few minutes of steaming is enough to maintain a tire, in theory, as long as the temperature does not drop below 150°C before the vulcanization is completed. However, when nitrogen vulcanization is used, high-temperature and high-pressure steam is first introduced, which will cause the temperature difference between the upper and lower sidewalls. To eliminate the vulcanization temperature difference between the upper and lower sidewalls, the location of the vulcanizing medium injection must be reasonably arranged, and the sealing and thermal pipeline system must be improved. . The purity of nitrogen used for vulcanization is required to reach 99.99%, preferably 99.999%, and it is recommended that enterprises prepare their own nitrogen system to reduce the cost of use. Insufficient nitrogen purity will affect the service life of the capsule. Applying the principle of "pressure-holding and variable-temperature" vulcanization of nitrogen vulcanization to the transformation of the traditional circulating superheated water vulcanization process, people have developed a vulcanization process that uses high temperature and high pressure steam and superheated water to replace the conventional circulating superheated water vulcanization process. During vulcanization, the high-temperature and high-pressure steam is introduced first, and after a few minutes, the circulating superheated water is switched in. After a few minutes, the return valve is closed to stop the circulation until the vulcanization is completed by latent heat. Using this new heating vulcanization method, according to theoretical calculations, its energy consumption is only 1/2 of the traditional vulcanization process. 8. Vulcanization process Temperature measurement. The key factors of high temperature vulcanization process Perform vulcanization temperature measurement to find the slowest vulcanization point in the product, and determine the vulcanization time based on this point. The effect is better than the previous two. Using this method can improve the vulcanization efficiency to varying degrees and improve the uniformity of the vulcanization degree. However, since only the external temperature is examined in actual production, the actual temperature of each part of the tire is not known, and the temperature is not fixed every time, so the result calculated according to the temperature measurement and the actual vulcanization result have a large error. The temperature field simulation and prediction of the vulcanization process of thick rubber products show that the uneven temperature is the main factor causing the uneven vulcanization degree of the tire casing. The rubber industry generally believes that a constant external temperature is an important condition to ensure quality, and it is necessary to do everything possible to achieve a constant temperature from the equipment. This is true for non-thick rubber products, but not for thick rubber products such as tire casings. The tire is heated and vulcanized in the model, and the heat is transferred to all parts of the tire through the model. Rubber is a poor conductor of heat, and the temperature rises slowly. There are obvious temperature gradients in various parts of the tire during the early heating period, and it takes a long time to reach equilibrium.

detail >

-

2019-07-20

The history of rubber additives

1. The first generation of rubber additives[1839~1904] In this era, rubber additives are represented by inorganic vulcanization accelerators. The rubber industry has entered the era of inorganic vulcanization accelerators, but there are also problems such as low acceleration efficiency and poor vulcanization performance.In 1839, vulcanization was discovered.In 1844, the inorganic vulcanization accelerator basic lead carbonate was discovered.In 1846, the foaming agent was discovered, and the sulfur chloride cold vulcanization method was discovered.In 1904, it was discovered that carbon black can be used in rubber.2. The third generation of rubber additives[1980~now] At this stage, the main characteristics of rubber additives are environmental protection and multi-functionality.From 1980 to 1981, the promoter NS was developed.In 1985, the environmental protection promoter MTT was launched.Since 1991, environmental protection additives such as non-nitrosamine additives, sulfonamides, zinc salt additives, sulfides, and anti-scorch additives have been developed and applied successively. Has invented ZBPD, TBSI, CBBS, TBzTD, TIBTD, ZDIBC, OTTOS, ZBEC, AS100 and other products.

detail >

-

2019-07-20

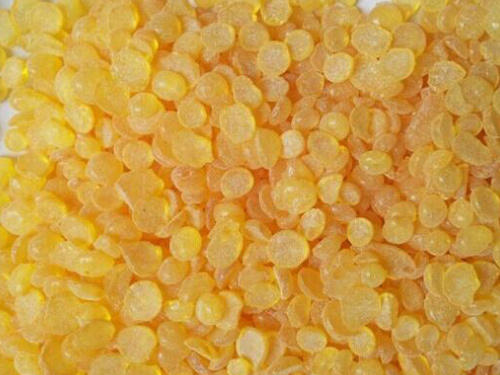

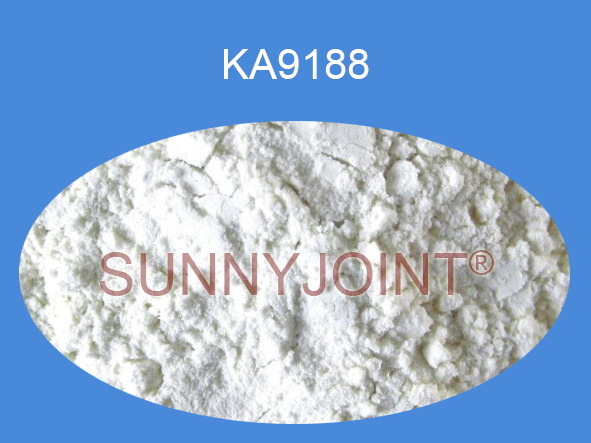

At present, the company has more than 30 kinds of products of SUNNYJOINT

At present, the company has more than 30 products of SUNNYJOINT, including accelerators, antioxidants, vulcanizing agents and other special additives. It also provides products in different forms such as oil-extended, granulated and ultra-fine products, which are widely used in tires, rubber hoses, rubber shoes, The production of latex, cables and wires and miscellaneous rubber parts is a necessity for rubber processing.

detail >

-

2019-07-19

Analysis of the combination of rubber accelerators

When selecting accelerators from the aspects of process performance and product performance, single use of accelerators often fails to achieve the desired effect. For example, although the accelerator DPG can give the vulcanized rubber high tensile strength and elongation stress, the sulfur speed is slow, the flatness is poor, and the vulcanized rubber has poor heat aging resistance; the accelerator TMTD has a fast sulfur speed and high vulcanization degree, but The processing safety is poor, and it is easy to scorch and oversulfur; the vulcanizates of thiazole and sulfenamide have higher tensile strength, good wear resistance, heat resistance, aging resistance, and good vulcanization flatness. In order to further increase the vulcanization speed and achieve higher use value, 2-3 kinds of accelerators are often used in the design of the vulcanization system in the rubber formulation to achieve the effect of complementing each other or activating each other, so as to adapt to the processing technology and improve product quality. need. When "accelerators" are used in combination, one type of accelerator is usually used as the main accelerator (called the primary accelerator or the first accelerator), and the other accelerator is used as the secondary accelerator (called the secondary accelerator or the second accelerator). The amount of the main accelerator is larger, and the amount of the secondary accelerator is smaller (generally about 10% to 40% of the amount of the main accelerator). Combined use classification: 1. Accelerators are divided into three categories according to acidity and alkalinity. One is acid accelerator (indicated by letter A): including thiazole, thiuram, dithiocarbamate, xanthate; the other is alkaline accelerator (indicated by letter B): including guanidine Class and aldehyde amines; third is the neutral accelerator (represented by the letter N): including sulfenamides and thioureas. Accelerators are classified into AB, AA, BB, NA, NB, NN, etc. according to the combination of acid and alkali, but commonly used are acid-base (AB), acid-acid (AA), and neutral acid (NA). 2. Accelerators are divided into five categories according to the vulcanization speed. Internationally, it is customary to compare the vulcanization speed of accelerators based on the effect of accelerator M on natural rubber. Slow-speed grade: aldehyde amines, thioureas; medium-speed grade: guanidines; quasi-super-speed grade: thiazole, inosinamides; super-speed grade: thiuram; super-speed grade: dithiocarbamate, yellow Orthoate. Combination skills: Generally, acid accelerator (A) type or neutral accelerator (N) type is selected as the main accelerator, namely thiazole and sulfenamide accelerators. As the main accelerator, thiurams are generally used in effective and semi-effective vulcanization systems. As the main accelerator, dithiocarbamate accelerators are often used in latex products and butyl rubber. As the secondary accelerator, alkaline accelerators such as DPG and H are generally used. Its role is to activate and promote each other. When sulfenamides are used as primary accelerators, secondary accelerators are generally not used. Because this accelerator can decompose accelerator M and amine compounds at the vulcanization temperature, M is an acid accelerator, and amine compounds are alkaline accelerators. It constitutes an acid-base (AB) combined system, but in order to speed up the vulcanization speed, a small amount of accelerator DPG or thiuram accelerator can be used together. The amount of accelerator DPG is generally 10% of the main accelerator. When the amount is too high, the vulcanization speed will tend to decrease. use and match: 1. Acid-base (AB) combined use (mutual activation) is a combined use method in which an acidic accelerator is the main accelerator and an alkaline accelerator is used as a secondary accelerator. The accelerator effect after the combined use is better than when A or B is used alone. Typically, thiazoles and guanidine accelerators are used in combination. For example, accelerator M is a quasi-super-speed grade, and accelerator DPG is a medium-speed grade, but the super-speed effect can be achieved after combined use, which is characterized by high vulcanization activity (fast starting point of vulcanization, fast vulcanization speed), tensile strength and fixed elongation of vulcanized rubber The stress, hardness and abrasion resistance are higher than that of a single accelerator. Accelerator M and DPG are theoretically effective when used together in equimolar. At this time, the setting speed and vulcanization speed of the rubber compound are fast, and the mechanical properties are also high, but it is easy to scorch, the vulcanization flatness is poor, and the process safety is poor. Therefore, in order to ensure process safety in actual production, the combined dosage of accelerator M and DPG is generally controlled at M:DPG=5:2~4 (mass ratio). In order to improve operational safety, the combination of accelerators DM and DPG is currently more commonly used, which is similar to the combined use of M and DPG, except that the start of vulcanization and the vulcanization speed are slightly slower. In fact, the combined use of thiazoles and hexamethylenetetramine is also effective. The combined use of accelerators M, DM and DPG is the development of the combined use of M and DPG. Among them, M and DM should be regarded as the first accelerator together, and DPG as the second accelerator. This combined method is suitable for use when the total amount of accelerator is large and the process operation requires good stability, and the increase or decrease of DM can be used to adjust the starting point of vulcanization. The AB type combined system has the following advantages: (a) It can shorten the vulcanization time or reduce the vulcanization temperature, and can reduce the amount of accelerators, so it can improve production efficiency and reduce production costs; (b) The vulcanization start point is fast, and it is suitable for non-model vulcanization requirements. Where the rubber material has a fast setting speed; (c) The tensile strength, fixed elongation stress and abrasion resistance of the vulcanized rubber are improved; (d) It makes up for the shortcomings of poor aging resistance when the accelerator DPG is used alone. Combination skills: 2. Acid and acid (AA) combined use (mutual resistance) This is the combined use of two different types of acid accelerators. After their combined use, the activity of the system is often suppressed at a lower temperature (referring to the operating temperature), thereby improving the scorch performance, but at the vulcanization temperature, it can still exhibit rapid vulcanization. effect. For example, when TMTD and M are used together, the conversion of part of TMTD into DM inhibits the activation of TMTD and improves scorch. Zinc dithiocarbamate is formed in the system, which plays a role of rapid vulcanization after the start of vulcanization. There are two types of AA commonly used in combination. One is that the primary accelerator is an overspeed or superspeed grade (such as TMTD or ZDC), and the secondary accelerator is a quasi-overspeed grade (such as M or DM). For example, in natural rubber, when one part of accelerator ZDC is used alone, the scorch time is 3.5 minutes. If the 10% amount is replaced with accelerator M, the scorch time can be extended to 8.5 minutes, while the vulcanization speed remains unchanged. , And make the tensile strength of the vulcanized rubber have a certain increase. The other is the accelerator M (or DM) as the main accelerator, TMTD as the secondary accelerator, and similar effects can be obtained after combined use. For example, the fiber carcass compound formula of bias tires can adopt this combined method, which has a slow start of vulcanization and a fast vulcanization speed. The starting point of vulcanization is slow, and the rubber compound has good fluidity before the initial vulcanization, which helps to improve the adhesion between the rubber compound and the fiber cord; the fast vulcanization speed can ensure that the inner layer of the rubber is heated later. It can be vulcanized synchronously with tread rubber. When the accelerator M (or DM) is used in combination with TMTD, if the amount of M (or DM) is about 1 part, the amount of TMTD is generally 0.05-0.1 part (up to 0.2 part or more in synthetic rubber). If the amount of TMTD is too high, the flatness of the vulcanization will decrease, and the fatigue crack resistance of the vulcanized rubber will decrease. This type of combined use is suitable for model products. After combined use, it does not increase the tensile stress like AB combined use, but it has a higher elongation and the product is softer. Combination skills: 3. Neutral acid (NA) combined use This kind of combined use can activate the neutral accelerator, thus speeding up the vulcanization speed of the system, but shortening the scorch time of sulfenamide to a certain extent. There are two typical NA-type combined systems. One is the combination of CZ (or NOBS) and M (or DM), which is more common in tire tread rubber and conveyor belt covering rubber formulations that use natural rubber and synthetic rubber. It has the characteristics of low scorch tendency, fast sulfur speed, good comprehensive performance of vulcanized rubber, and good aging resistance. 4. In combination with alkali (NB): CZ (or NOBS) and TMTD (or ZDC) are used together. This combined method can replace the combined use of thiazole and guanidine. Compared with the combined use of thiazole/guanidine, it has less total amount of accelerator, faster sulfur speed, and scorch time. It is longer, the degree of cross-linking is increased, and the compression set is smaller. The disadvantage of this system is that the flatness is slightly worse.

detail >

Copyright © Shenyang Sunnyjoint chemicals co.,ltd 1999-2025 All Rights Reserved